RISO’s unique inkjet technologies based on oil-based pigment ink offer heatless imaging for outstanding performance in handling the demands of high-volume printing.

RISO’s unique inkjet technologies

based on oil-based pigment ink

offer heatless imaging

for outstanding performance

in handling the demands

of high-volume printing.

The straight-path paper feeding system delivers paper horizontally to enable high-speed printing with precise alignment. FORCEJET technology ensures an optimal paper feed that matches the amount of ink emitted from the ink heads.

RISO’s inkjet printers are capable of high-speed, full-color printing using inkjet technology primarily designed for various applications. The print heads are arranged in parallel for single-pass printing on A3 short-edge paper. The ComColor GL Series prints at 165 ppm for A4 simplex printing. Also, the VALEZUS T2200 prints at 330 ppm for A4 duplex printing.

RISO uses a line-type inkjet system suitable for high-speed full-color printing. Developing an in-line head, it can print an entire line on the short side of A3-wide paper at once, deploying 4 or 5 colors in parallel, depending on the model. By synchronizing the feed belt speed and ink drop from the print heads, these printers precisely control a massive number of nozzles.

RISO inkjet printers deliver high-precision printing by using proprietary oil-based inks designed for ultra-high speeds. Sensors monitor paper feed and adjust timing for synchronized ink drop. Furthermore, controls to minimize paper stress and shorter paper feed intervals enhances image stability, enabling high-speed and precise full-color printing.

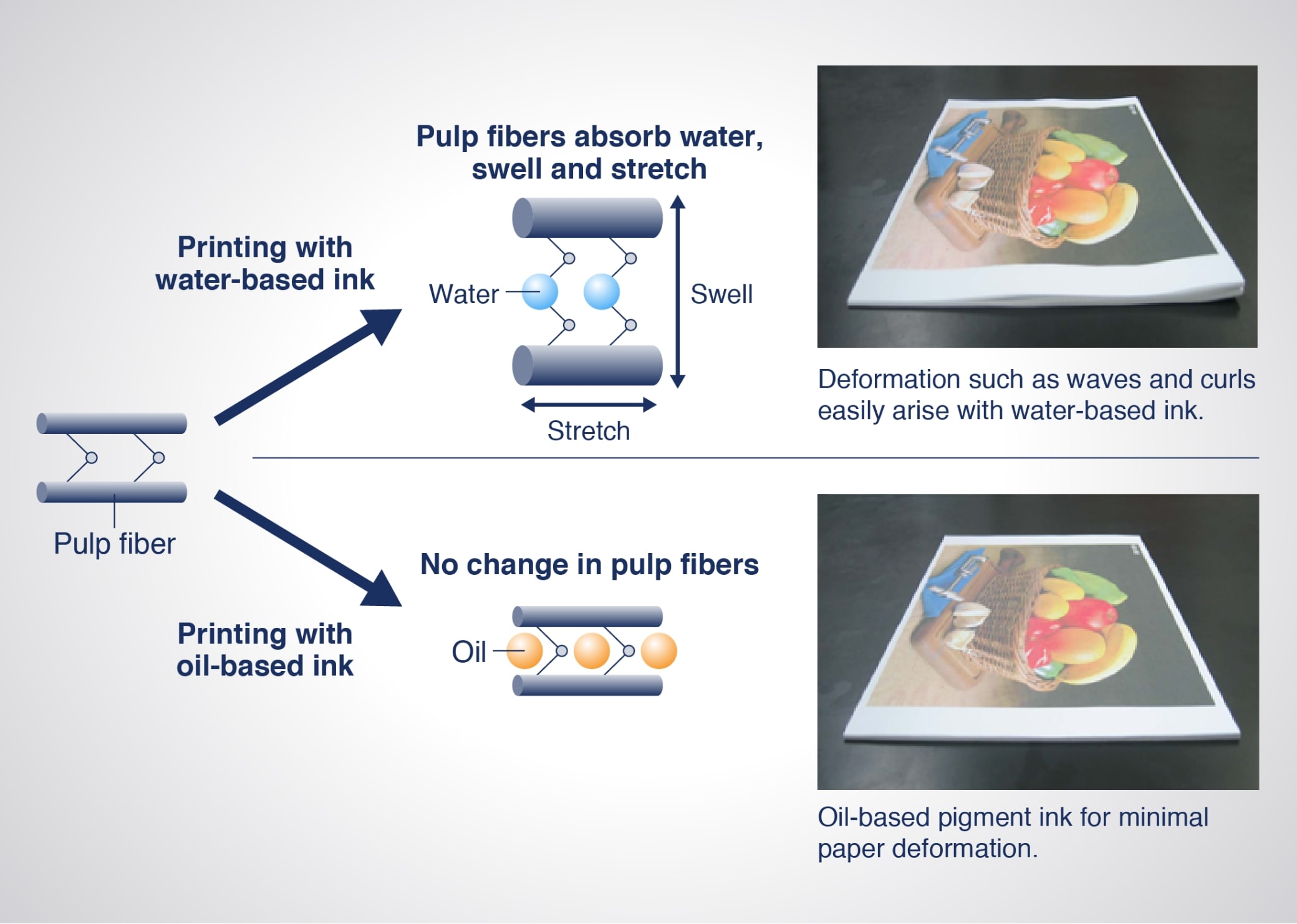

While most of the inkjet printers use water-based inks, RISO printers employ oil-based inks suitable for high-speed full-color printing. Oil-based inks minimize paper ripping and curling compared to water-based inks, enabling smooth paper feeding and post-processing (collation, book-binding, etc.).

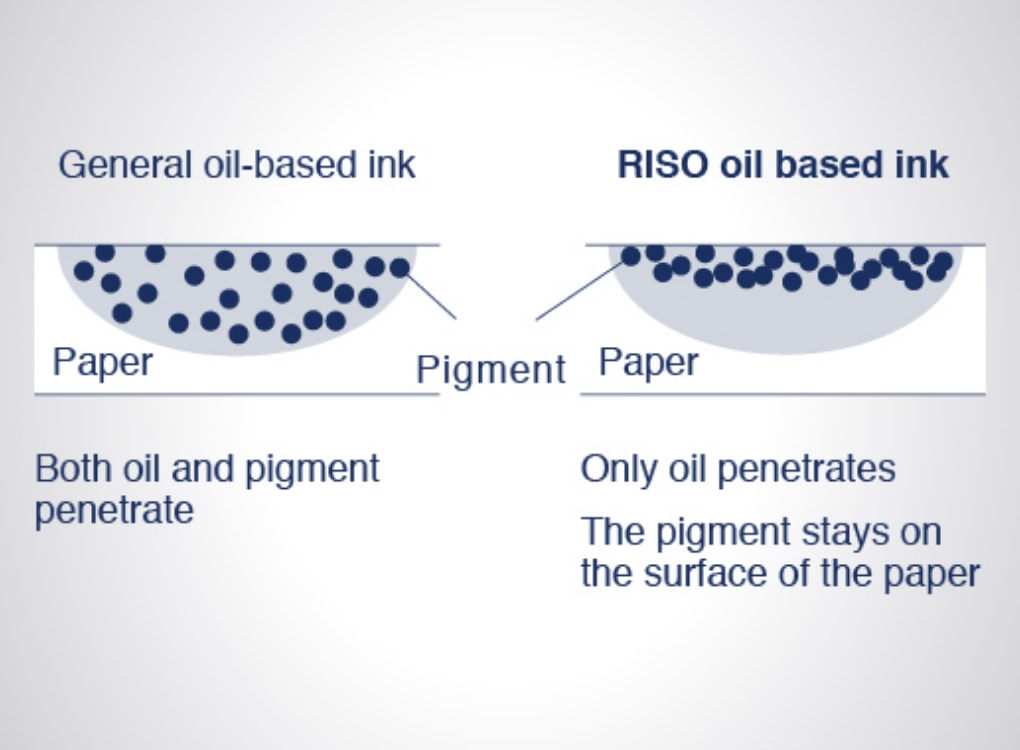

RISO’s unique oil-based ink is designed to prevent ink from penetrating to the back side of the paper, enabling high-speed duplex printing while maintaining superior output quality.

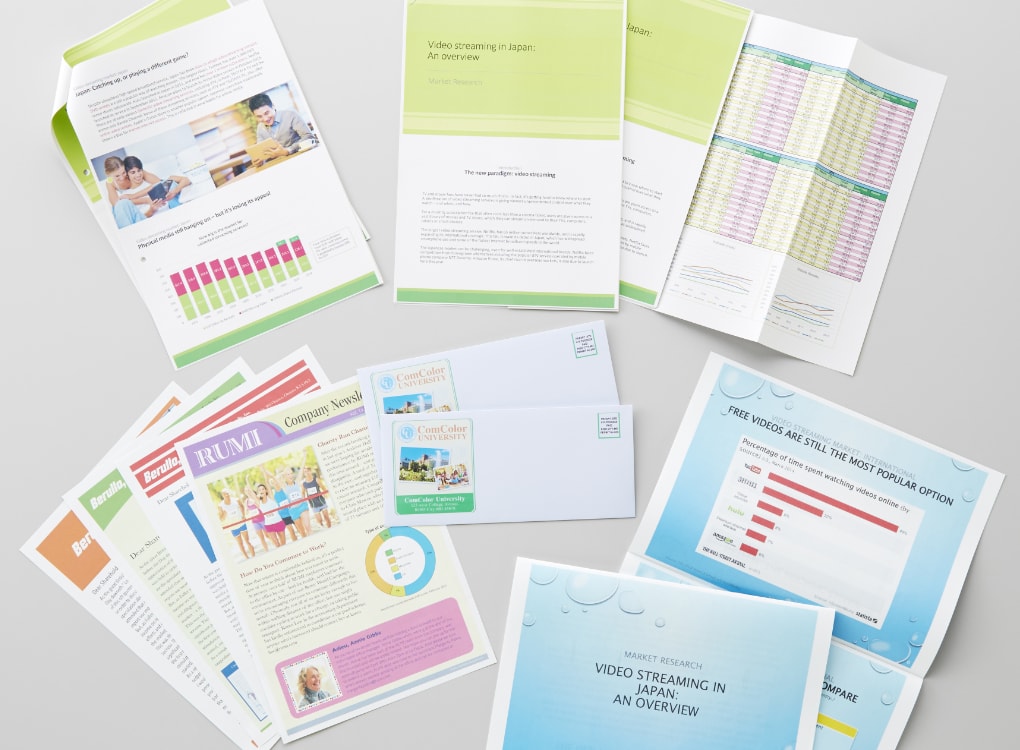

RISO’s oil-based ink effectively prevents bleeding when writing on printed documents with water-based pens. It also offers excellent light resistance to minimize fading, making it ideal for documents requiring long-term storage.

With RISO’s oil-based ink, there is no ink head cap, and the frequency of head cleaning is low. This makes high-volume printing with RISO inkjet printers efficient, ultimately saving time.

RISO's oil-based ink minimizes paper ripping or curling after printing, ensuring smooth post-processing tasks, such as inserting into the envelopes and book-binding.

RISO's innovative cold-printing system operates without the need for heating elements, eliminating the risks associated with drying inks and toner. This heatless imaging technology enhances print quality while significantly reducing energy consumption, making it an efficient solution for high-volume printing environments.

Unlike traditional toner-based machines, RISO's inkjet printers do not produce toner dust during the printing process, contributing to a cleaner working environment. Additionally, their compact design not only reduces the overall equipment footprint but also minimizes initial investment costs, making RISO inkjet printers an economical choice for businesses looking to optimize their printing operations.